New building in Mettmann: on schedule for completion

A new service centre is being built in Mettmann. Construction work is progressing according to plan. The hall part of the new building is already ready for occupancy. The administrative wing will follow in the first quarter of 2025.

Transforming with SAP

As part of a comprehensive digital transformation, we have completely modernised our IT landscape and installed an SAP software solution under the motto 'Cloud first'. The trade magazine 'Betriebstechnik und Instandhaltung' has now published a report on this.

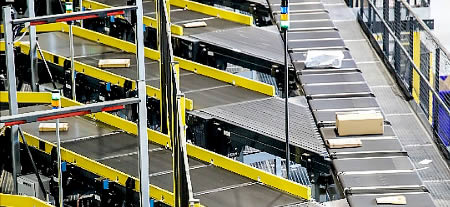

We install top performance

In the air hub of a global parcel service provider at Cologne-Bonn Airport, a SAMONT team of around 100 people is installing eight additional kilometres of conveyor and sorting technology - in part during ongoing operations.

Top ranking for SAMONT

After 2021 and 2022, SAMONT is also part of the exclusive circle of the 1000 fastest-growing companies in Europe in 2023. This is the result of the annual ranking of the British business newspaper Financial Times.

REFERENCES

More than 300 proofs of confidence worldwide

In the past financial year, the number of projects completed by our teams exceeded the 300 mark for the first time - proof of the trust that customers at home and abroad place in SAMONT's performance.

Here is a small extract from our project list:

Parcel service provider - Poland

Installation of 600 metres of conveyor equipment including spiral chutes, telescopic conveyors and steel platforms.

PET packaging manufacturer - Netherlands

Installation of conveyor equipment including a 2D shuttle system as part of a major automation project.

Online retailer - Italy

Installation of conveyor and sortation systems in a new logistics centre.

Food retailer - Netherlands

Installation of storage and picking equipment for the assembly of up to 2 million retail units per week.

Austrian Post - Austria

Installation of high-performance parcel sorting technology with a capacity of up to 20,000 parcels per hour.

Online retailer - Germany

Installation of 4 kilometres of conveyor equipment in a new distribution centre.

Online retailer - United Kingdom

Installation of 12 kilometres of conveyors with 254 chutes, 16 spiral conveyors and 800 metres of crossbelt sorters in a logistics centre in just 15 weeks.

Online retailer - Switzerland

Installation of semi- and fully automated conveyor and sortation equipment as part of the expansion of a logistics centre.

Food retailer - Austria

Electrical installation of tray, pallet conveyor and order picking equipment in a central warehouse.

OUR REFERENCES